Suzhou Kzone Equipment Technology Co., Ltd, with its business scope covering research and development, design, manufacturing, sales, and after-sales service, was established in Xinzhuang Industrial Park, Changshu New & Hi-tech Industrial Development Zone, Suzhou in 2011. The company is committed to the production, research and development of high-end wet process equipment in the fields of panel displays, photovoltaics, and semiconductors, such as high-precision cleaning, development, wet etching, and photoresist (PR) stripping, as well as the supporting areas of environmental protection and intelligent data, such as online waste liquid recovery system, robot application and other key automation systems, we are a comprehensive solution provider for high-end wet process equipment and process technology with high-tech enterprise qualifications.

Successfully developed the industry's first back polishing and etching cleaner

Entered the field of panel displays and semiconductor packaging:Successively completed the research, development and mass production of G2.5-G5.5 wet etchers;The flexible display material cleaner received certification for the first major equipment (set) in Jiangsu Province

PV:Started the development and successfully realized the mass production of the first-generation wet equipment for black silicon (BSi)

FPD:Conducted deep cooperation with industry customers, batch delivered various types of G6 AMOLED equipment, wet etching equipment Received certification for the first major equipment (set) in Jiangsu Province, completely breaking the monopolies of imported equipment manufacturers

PV:Successively completed the development and mass production of the second and third generations of wet equipment for black silicon (BSi);Launched the new generation of efficient crystalline silicon texturing cleaner, alkaline polishing and etching cleaner and other comprehensive equipment into the market

FPD:All-around breakthrough in the G6 mask cleaning, delivery of complete set of wet equipment for flexible On Cell panel;Batch delivered G8.5 and above oversized full series wet process equipment, diligently worked on layout for display processes and technologies in the future;

PV:Focused on layout of wet process equipment for TOPCon, conducted R&D cooperation with multiple customers in the industry, and achieved pilot production.

The newly built wet process intelligent equipment production base, R&D center, and physical and chemical laboratory have been put into use with stable operation;

FPD:Launched the LTPO wet process solution for the first time in China, entered the display glass substrate industry chain, and successfully delivered the first FMM process equipment in China;

PV:Achieved mass delivery of TOPCon, completed the validation of high-capacity models and put them into the market.

Provincial-level Engineering Research Center

Provincial-level Engineering Research Center

Provincial-level SRDI Small Giant Enterprise

Provincial-level SRDI Small Giant Enterprise

Provincial-level Engineering Technology Research Center

Provincial-level Engineering Technology Research Center

Provincial-level Enterprise Technology Center

Provincial-level Enterprise Technology Center

Provincial-level Industrial Design Center

Provincial-level Industrial Design Center

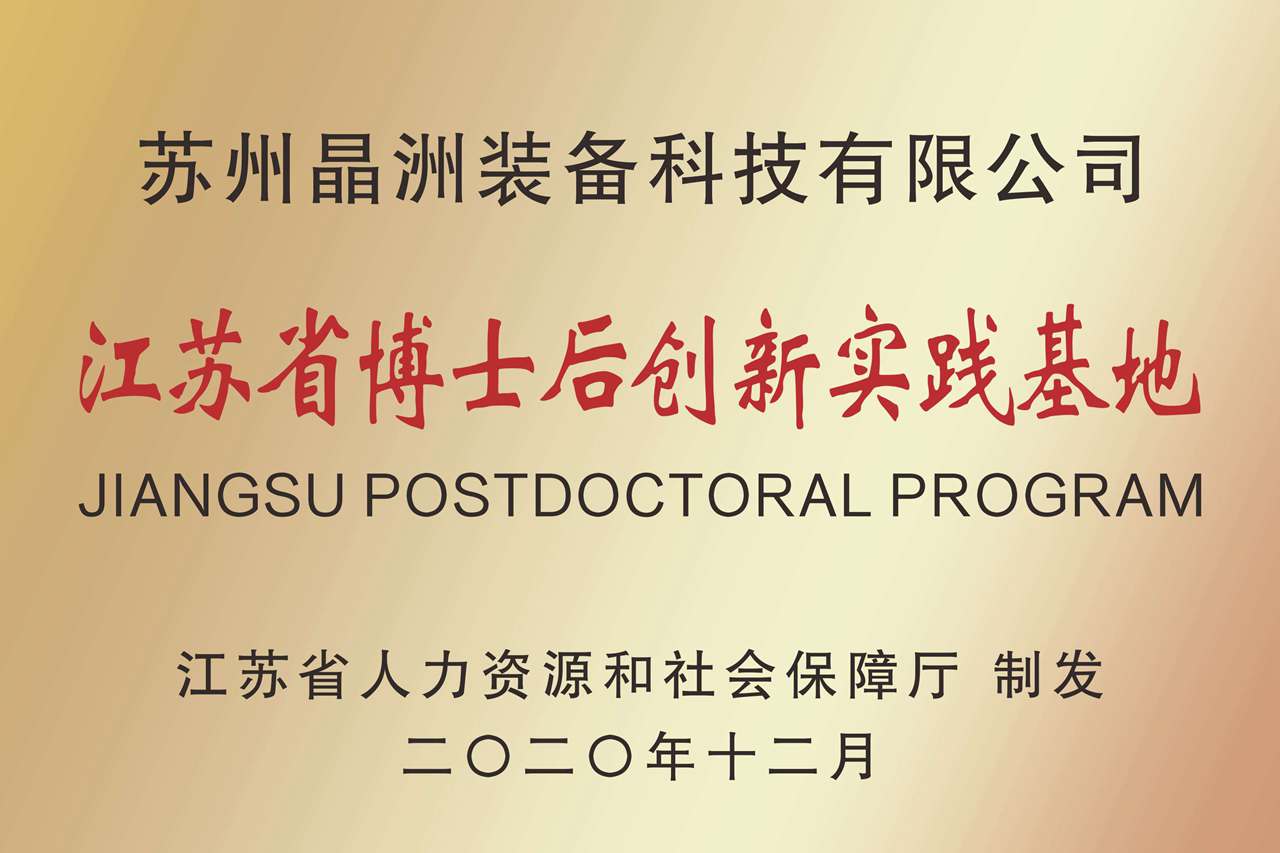

Provincial-level Postdoctoral Innovation Practice Base

Provincial-level Postdoctoral Innovation Practice Base

High-tech enterprise

High-tech enterprise

National Intellectual Property Advantage Enterprise

National Intellectual Property Advantage Enterprise

The core team is composed of industry elites with over 10 years of experience and rich experience in high-end projects in the high-tech industry;

In the technical R&D team, those carries a master/doctor degree accounts for 15%, bachelor degree for 80%, and college degree for 100%, in addition, they also have intermediate title or above as engineer and industry expert;

We maintain a long-term strategic cooperation relationship with many leading enterprises, well-known universities, and research institutes in the industry.

Professor at Tsinghua University and former Deputy Director of the Beijing Tsinghua Research Center of Liquid Crystal Technology Engineering. Professor Zhang presently is a member of the Strategic Advisory Committee of BOE (Group) Technology Co., Ltd. and director of Hefei Visionox Technology Co., Ltd. He has been researching in the field of FPD for decades and had a profound impact on the technology application and development of the FPD industry.

Professor and Doctoral Supervisor at the School of Software and Microelectronics, Peking University. Professor Wang directed and participated in multiple national and provincial "973", "863", 02 projects and other scientific research projects. He presently serves as Deputy Director of the Technical Committee of the National Engineering Laboratory for FPD Glass Technology and Equipment, and a member of the Expert Committee of the National Engineering Laboratory of AMOLED Process Technology.

Doctor/Professor/Doctoral Supervisor, currently serving as Deputy Director and Professor of the Department of Environmental Science and Engineering at Fudan University. Professor Dong’s main research areas include environmental chemistry, pollution control, and environmental microbiology, especially the study on the conversion mechanism of organic pollutants. The projects led and completed by him include "Application of transient spectral analysis technology on the study of conversion mechanism of perfluorinated surfactants".

Doctoral Supervisor at the School of Physical Science and Technology, Soochow University, and a member of the PV Committee of the China Renewable Energy Society. His research areas cover preparation and application of new PV materials and devices, multifunctional optoelectronic thin-film materials and devices, and nano metal particles.

We have technologically leading position in many fields and have constantly gathered high-tech talents to

ensure stable development and long-term technological advantages of our company;

We invest over 10% of our annual revenue into R&D for more new technologies!